Industrial

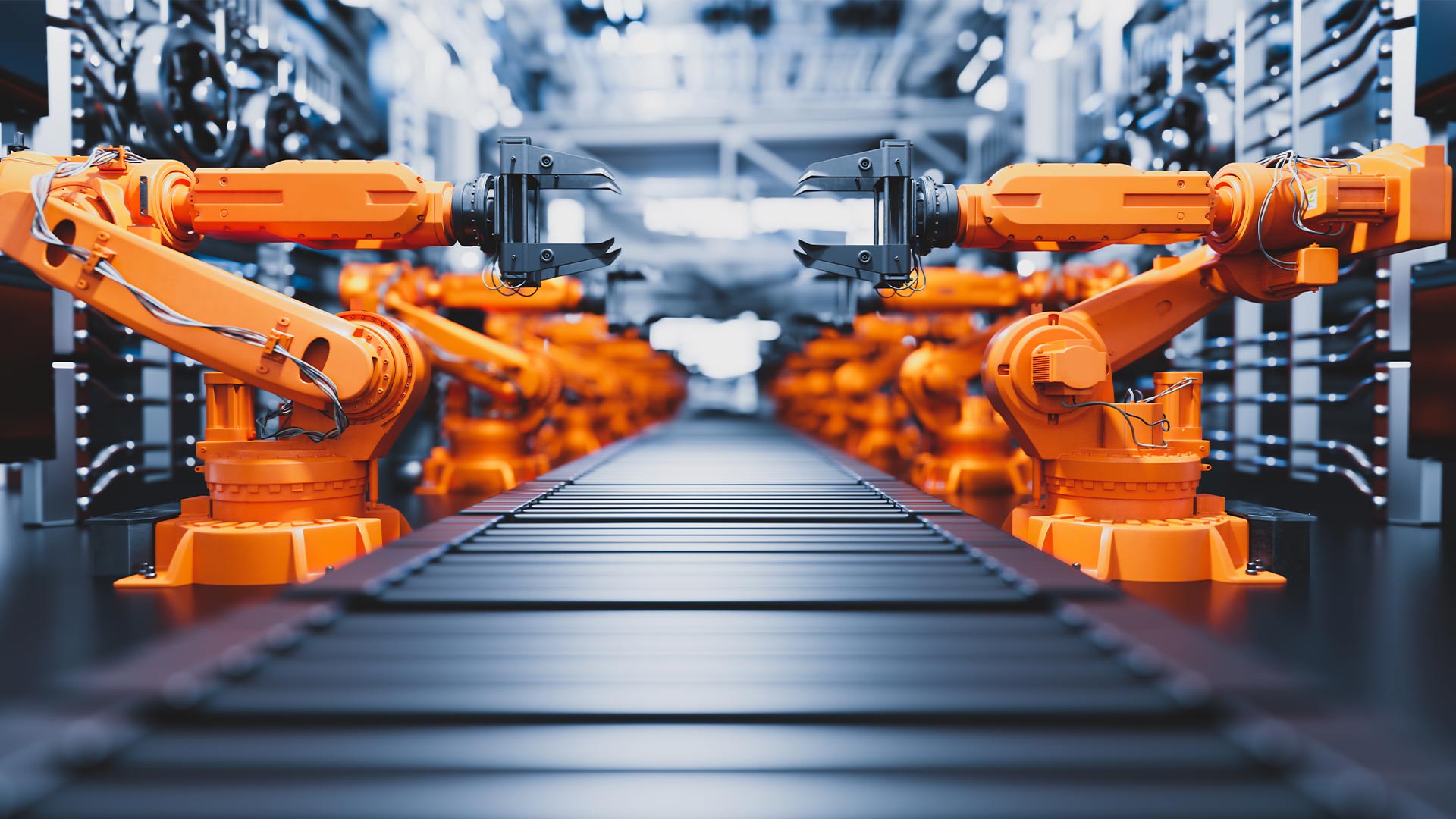

Improve supply chain efficiency

Overview

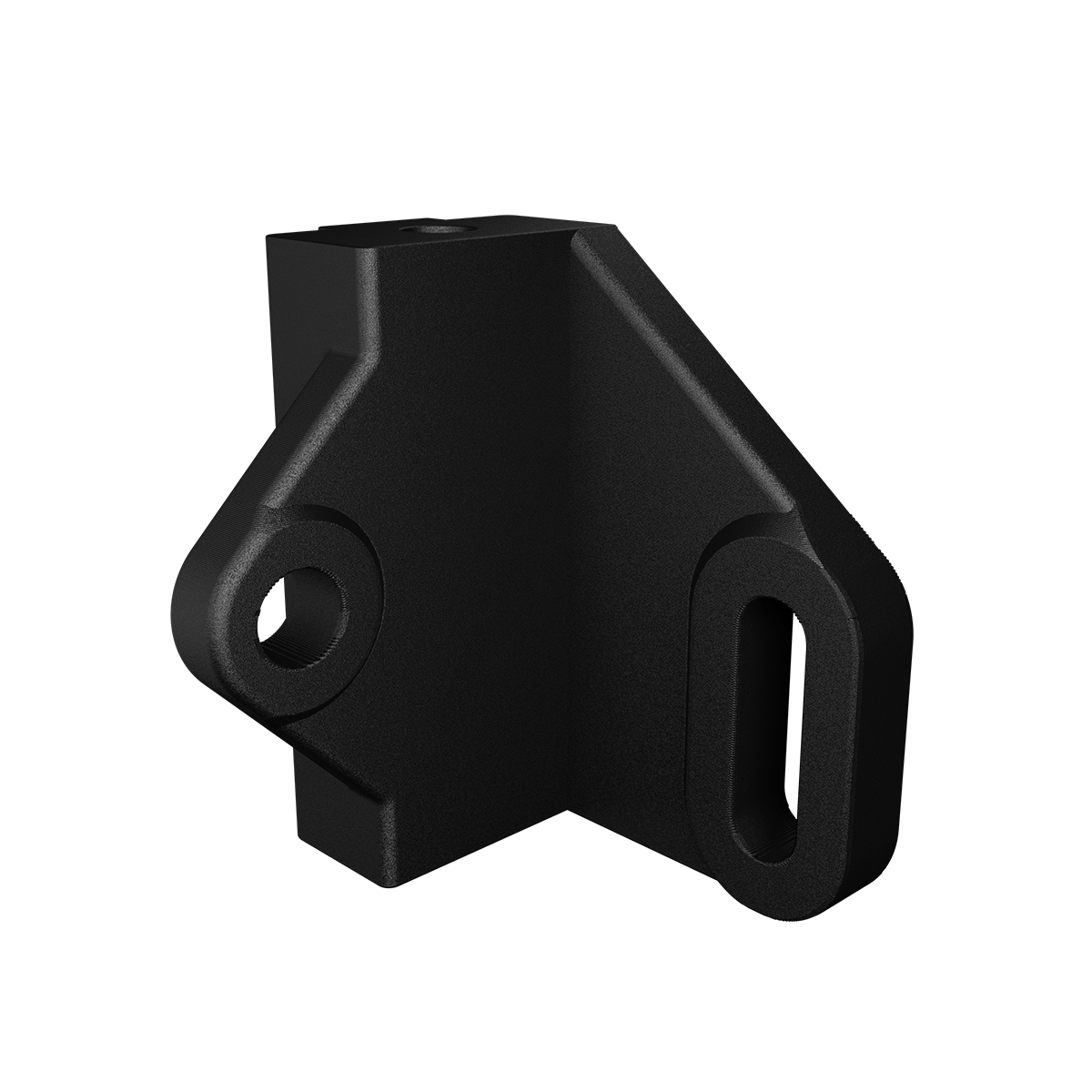

The world of manufacturing is undergoing a drastic change, moving from mass production to customized production to meet consumer demands. This is why it is of vital importance to have suitable and customized tools to optimize the processes of each plant, taking advantage of the freedom of design and production offered by Roboze additive manufacturing systems. By combining these advantages with high performance materials and guaranteed repeatability of the printing process, it is possible to create tools, equipment and supports that are perfectly customized for every need.

Advantages

Resources

Discover how Roboze is supporting companies in optimizing their production processes.