What is an Industrial 3D Printer?

Industrial 3D printers are machines that allow the physical realization of a 3D model project through modeling software or through reverse engineering, with the use of 3D scanners capable of replicating a digital project elaborated with computer aided design, or CAD.

Industrial 3D printers are based on an additive manufacturing method. Unlike traditional methods, which subtract material from solid, 3D printers form the three-dimensional object by depositing material layer by layer through different techniques. "Industrial printing" is defined when the 3D printed parts comply with the technical production requirements of the companies, both for finished products and for functional prototypes.

According to Chuck Hull, inventor of stereolithography, first to bring rapid prototyping into commerce, the definition of 3D printing is:

"A system for generating three-dimensional objects by creating a cross-sectional pattern of the object to be formed at a selected surface of a fluid medium capable of altering its physical state in response to appropriate synergistic stimulation by impinging radiation, particle bombardment or chemical reaction, successive adjacent laminae, representing corresponding successive adjacent cross-sections of the object, being automatically formed and integrated together to provide a step-wise laminar buildup of the desired object, whereby a three-dimensional object is formed and drawn from a substantially planar surface of the fluid medium during the forming process”

Industrial 3D printers are becoming an increasingly important element for manufacturing companies that intend to optimize their production by supporting traditional methods, unable to respond to new market needs. There are several sectors where industrial 3D printers can be useful and make a difference: Manufacturing, Energy, Mobility, Aerospace, Education and Medical. The advantages of using industrial 3D printers in a company are many and mainly linked to logistics factors, production optimization, cost reduction, internalization of the production of finished parts (therefore local production), reduction of transport and emissions, creation of a digital warehouse.

Today, the largest user of Roboze 3D printing technology is the manufacturing sector, with 26% of applications. Having a professional 3D printer in your company can be a revolution for your business: in this article we will focus on the characteristics and advantages of using an industrial 3D printer compared to desktop/consumer solutions, and we will illustrate various cases of application of 3D printing in automotive, aerospace, manufacturing, energy sectors.

Types of 3D printing technologies

There are several 3D printing technologies useful for making parts according to profiles and printing parameters, each with its own limitations and advantages. Among the most used we include:

- FFF 3D printing technology (Fused Filament Fabrication)

It is the most widely used additive method in the world which falls under fused solids based technologies. In fact, it involves the fusion of a filament, which is extruded and deposited layer by layer on a printing bed of different dimensions with respect to its volume. It is the most popular 3D printing technology as it is easy to use and more versatile with respect to production materials compared to other additive methods.

- SLA 3D printing technology (Stereolithography)

SLA technology also boasts good material versatility but involves a photopolymerization-based process in which a laser, layer by layer, solidifies a liquid resin. Among the various technologies it boasts the best graphic resolution but, compared with an FFF technology, it is less mechanically performant as it is structurally more fragile than the fused filament. It is also limiting in terms of print size.

- SLS 3D printing technology (Selective Laser Sintering)

The SLS method is based on a melting powder technology. In fact, the object is made using a powder material that is compacted by a high-power laser capable of fusing small particles of polymer powder. It is usually among the most expensive 3D printing technologies, but it has the advantage of achieving greater geometric complexity of parts because the unfused powder supports the part during printing, eliminating the need for supports.

3D Printing materials: what material is used in 3D printing?

3D printing materials play a key role: in the form of filament, pellets, resins, and powders, each of these addresses specific needs of the finished object. There are various families of 3D printing materials, but at the industrial level the most widely used 3D printing categories are:

- Plastics

Among the most used thermoplastics, especially in the engineering sector, it is important to mention polyamide (nylon) for its properties of chemical wear and mechanical resistance. Loaded with carbon fiber it becomes a strategic option for the production of tools, jigs and fixtures for manufacturing companies. In recent years there has been a growing demand for high performance, strong and functional polymers and composite materials, capable of withstanding harsh environments and high temperatures, to support the shift of technology from a mere prototyping solution to production system of the most advanced applications.

- Metals

The most widely used 3D printing technology for metals involves melting metal powders through a powerful laser. Given the advantages of additive manufacturing over traditional manufacturing, it is not surprising that it is a preferable choice of companies, which are already accustomed to producing components with these materials. Here, too, we find various options to the chemical-physical and mechanical properties required by the market. Think of stainless steel, or aluminum, bronze or silver, up to titanium, not entirely widespread due to high costs.

- Ceramics

"Younger" than polymeric and metallic materials in 3D printing, ceramics have seen their first rise only recently. Primarily used for prototyping and research and development, its growth in adoption by operators is increasingly driving investments to refine the technology for the production of finished components. It receives great interest from sectors such as aerospace and medical.

- Resins

With 3D printing technology that uses liquid resins it is possible to obtain very precise components with excellent surface resolution. Here too, the versatility in choosing the most suitable material is very wide but, compared to the filaments of the FFF method, they are slightly more expensive and include more post-printing phases to obtain more compact and stronger objects. It is highly appreciated in the jewelery and dental sector.

However, industrial 3D printing must prove its capabilities against established systems such as molds, milling and turning, ensuring quality standards and repeatability and process control.

Advantages of using an industrial 3D printer

The advantages of using an industrial 3D printer are:

- Scalability, local production, Supply Chain optimization

With Roboze industrial 3D printing systems, it is possible to get the same part anywhere in the world. This revolutionary approach is moving production from low-cost areas directly to the point of use. The result is more local assembly centers that allow you to produce a finished part whenever and wherever needed, without having to rely on imports. All this allows to significantly shorten the Supply Chain, reduce the number of intermediaries, improve control along the supply chain and reduce lead time on the market.

- Flexible, repeatable and customizable process

Industrial 3D printing solutions such as Roboze’s offer the possibility of setting up an ecosystem completely aimed at precision, repeatability and process control, with greater freedom in product customization without having to pay for the development and construction costs of traditional manufacturing. The approach is much more flexible, as it allows companies to produce small customized batches quickly and effectively, reducing the risks associated with changing market demands.

- Produzione of end-use parts (not only prototypes)

The industrial technological ecosystem associated with the use of composite materials, such as Carbon PA PRO or Carbon PEEK by Roboze, allows the production of finished functional parts and not just prototypes.

- Creation of a digital warehouse, reduction of waiting times

Having with 3D printing the possibility of creating individual components with very low waiting times and at low cost, it becomes reasonable to integrate the physical warehouse with a digital inventory containing the three-dimensional models of the spare parts. In this way, companies can design their product centrally and have spare parts manufactured locally whenever and wherever needed, mitigating risks and costs related to warehouse management. The implications in terms of logistics are also significant, reducing the waiting time for the customer and reducing the carbon footprint of the goods.

- Reduction of transport and emissions

Bringing the value of production to the point of use certainly means reducing transport, and therefore the related costs and carbon footprint. Furthermore, using super-polymers and composite materials also means having the possibility of replacing metal by obtaining lighter parts. This is a very important factor for industries such as aerospace and defense, transportation and automation, where mass reduction plays a key role in determining efficiency. In these industries the lower the weight, the lower the energy or fuel consumption and the higher the efficiency of the processes: just think that in the aviation sector every kilo saved leads to 73 tons of CO2 emissions less per year.

Why you should have an Industrial 3D printer?

Imagine a critical project, where you want to increase the efficiency of the production process in your company. If you have long prints and expensive materials, you do not want your printer to fail when you are committed to time sensitive delivery schedules. Being late with the delivery will cause higher costs and, worse, lost customers. Here’s why you should have a Professional 3D printer in your company:

- Automation

Things cannot be repeated if the process isn't automated: desktop printers don't have automation for many functions. For example, build plate alignment and z-direction calibration are usually done manually with the help of a feeler gauge and can generate inaccuracies in the process. Some advanced desktop printers, on the other hand, have an automatic build plate calibration using capacitive sensors, but this process is temperature dependent and does not take into account the wear of consumables, ultimately resulting in inaccuracy.

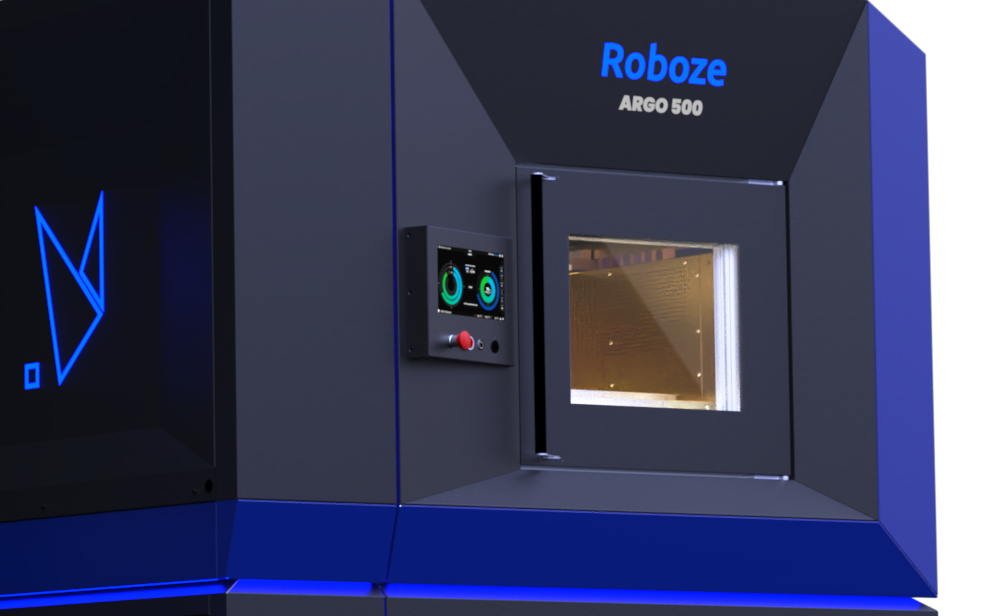

On every industrial 3D printer, such as the ARGO by Roboze, the calibration of the print bed and the Z axis are performed automatically before each print in less than a couple of minutes, obtaining a more precise and repeatable process.

To give another example, during the extrusion process the nozzles become dirty: on desktop printers, the user must manually clean the nozzle after the printing process, when the printer is off; on industrial 3D printers such as Argo there is an automatic nozzle cleaning, which takes place directly during printing with a line of code in the gcode file.

- Dryer

A typical property of many polymers is hygroscopy, defined as the ability to absorb moisture from the surrounding environment. The water molecules can interact with the polymer and create a depolymerization process that affects the properties of the material, leading to a degradation of its aesthetic, chemical, and mechanical characteristics.

Subjecting a wet filament to the printing process causes the water inside to evaporate, creating air bubbles in the extruded material. This results in low adhesion between layers, deterioration in surface finish, oozing, stringing, warping and continuous clogging of the extruder - this happens all the time on desktop 3D printers.

Some printers use dehydrators or vacuum chambers to dry the filaments. There are limitations with these solutions: silica gel replacement, limited temperatures, and poor integration with printers.

The Roboze ARGO professional 3D printers, on the other hand, are equipped with the high temperature dryer (HT), a steel device designed to dry the filaments during the entire 3D printing process. This system is fully integrated into the printers, allowing them to load filament and change the spool automatically.

- Vacuum system

The first layer plays a key role in 3D printing. For this reason, the print bed must ensure excellent adhesion so that the piece, especially in the case of large prints, does not move or deform during the extrusion process.

Desktop printers offer several options for adhering parts to the build plate: glass plates, microporous surfaces, or carbon laminates to which you can apply vinyl glue or hairspray.

Industrial 3D printers such as the Roboze PRO and ARGO series, on the other hand, use polymeric films that are fixed thanks to the vacuum system. Following simple rules of chemical affinity, each filament is associated with a specific polymeric film which always guarantees perfect adhesion of the first layer. This solution speeds up and simplifies the commissioning operation and allows to keep the tolerances low, avoiding any deformation even at high temperatures.

- Motors

The motors that move printers can be very different: the most used, especially in desktop printers, is the stepper motor. One of the frequent issues with this motor is the loss of step that, in some cases, leads to the failure of the job or evident inaccuracies of the part.

With the advent of brushless motors on ARGO Automate systems, the process control allows for increased speed and precision. Furthermore, the brushless motors are more reliable and increase the accuracy of the finished part.

- Authentication steps

Everyone can use a desktop printer! In some cases, this might not be an advantage: there might be intellectual proprietary files that need more security. ARGO systems allow different authentication levels to protect your data. Depending on the role in the company, users will have different capabilities on the printer, adding levels of security. This feature helps with the traceability of the entire production process: from raw material to the last operator opening the machine after the job. Anything that could go wrong during the process is immediately tracked and identified.

Difference between desktop printers and industrial printers

Desktop printers have the advantage to help with the mass utilization of 3D printing, but industrial printers are the ones that ensure high quality of the printed parts.

We will go into more details on these main differences between desktop and professional 3D printers:

- Build chamber

- Maintenance

- Process control

- Accuracy and Repeatability

- Material choice and properties

- Cost

- Maximum build size

- Print success rate

- Automation

- Dryer

- Vacuum system

- Motors

- Authentication steps

The importance of a closed Chamber

Hobbyist 3D printers usually work in an open chamber, without a controlled printing environment. This brings the printing process to be strongly dependent on the external agents to which it is subjected. For instance, air and thermal fluctuations in the room where the printer is operating affect the part quality in your printer.

On the other hand, having a closed chamber allows for more control and protection from the external environment and any thermal or air fluctuations. This is the reason why professional printers like ARGO work in a controlled environment.

Some high-performance materials require processing in high-temperature ranges. In these cases, the heated chamber is mandatory to ensure the maximum quality of the printed parts. In ARGO printers, build chamber conditions are controlled and monitored through 4 sensors positioned at the 4 angles of the printing chamber. It is possible to have precise information on the operating temperature and automatically adjust the temperature to its optimal setting.

3D printer maintenance, the advantages of the Beltless System

Desktop printers stop printing for many different reasons and need maintenance steps to get back in shape. Their motion mechanism involves belts, but a printer with belts must be maintained more frequently, at least once a month, opening the device, and tensioning the belts. This operation needs dedicated tools and may require a whole day of downtime.

The positioning error is drastically reduced if you substitute belts with the Beltless System. The helical gear allows for simultaneous and progressive transmission of the load over several teeth, and this grants smooth sliding between pinion and rack reducing noise, wear, and localized overheating.

Do Roboze 3D printers require maintenance?

With ARGO printers, the maintenance time is reduced by 75%. It consists in applying Teflon grease on the axes that are greased in less than 2 hours, requiring no tools and low downtime. Everything has been designed to decrease the machine downtime. Maintenance is reduced on ARGO printers also thanks to the high-quality electronics. The operations are easier thanks to the PLC system that allows for advanced diagnostics that identify the modules to replace or maintain.

The physical, logistic, and commercial presence of Roboze and B&R both in Europe and in the USA, allows to drastically reduce the delivery times for spare parts.

3D printer process control

Controlling the 3D printing process is the first step towards a repeatable procedure. To do so, different printer manufacturers have worked on ways to monitor and trace every step. How do printers differ on process control? Let’s have a look at it:

- Desktop 3D printers are equipped with basic wired controls that can monitor basic functions inside the printer;

- Professional 3D printers very often have different systems for the process control, like PLC modules.

Roboze ARGO 500 is equipped with the Roboze Automate system that allows evaluation of all the parameters coming from the sensors, ensuring the user is always aware of the condition of every component in the printer to reduce the need for maintenance operations. The PLC module, together with an advanced diagnostic system, provides a detailed overview of the operations performed by the machine during the production phase. Thanks to the Roboze Automate System, each PLC component is robust and interchangeable, keeping the automation always in step with the latest technologies.

Industrial printers also have filament feed sensors to pause the machine when the filament in the feeding system breaks or runs out.

3D printing: Accuracy and Repeatability of the process

Typically, 3D printers have a motion transfer system that involves belts, subjected by their nature to issues like deformation, wear and loss of calibration over time. These factors, associated with high clearances and low precision, make the deposition of fused filament inaccurate and unrepeatable over time.

By removing the belts and introducing a direct mechatronic movement of the X and Y axes, Roboze’s Beltless System is aligned with CNC machines, providing the 3D printing mechanics with true micrometric tolerances, making the process repeatable and accurate.

How to achieve improved properties on printed parts with different materials

Desktop 3D printers have a limited range of materials that can be used, typically the most common plastics like PLA and ABS. They are unlikely to utilize composites or the most challenging high-performance polymers. Their limitation is mainly due to the temperature limit of an extrusion head that cannot reach 300 °C / 572 °F. To print high-performance materials and composites, extruders must withstand the melting temperature of these materials and also apply proper cooling.

Roboze has developed the HVP extruder (aren’t you familiar with the extruder? We talked about it in an article on ‘what does a 3D printer need to print PEEK’), that can reach up to 450 °C / 842 °F, to maximize the quality of the printed parts through a compressed air refrigeration system that facilitates the extrusion of high viscosity filaments. Thanks to the internal ceramic narrowing and the cooling system that allow for an optimized polymer extrusion, the Roboze HVP extruder solves the high viscosity issue for high-performance polymers and composites like PEEK, UltemTM AM9085F and Carbon PEEK.

There are a few desktop printers that claim they print PEEK. That is true, but the major difference between that and an industrial printer is in the crystallinity of the printed part. Printers with a heated chamber set to the correct temperature, allow for a full crystallization of the polymer. Without a heated chamber the material comes out of the printer in its amorphous state, resulting in lower mechanical, thermal, and chemical properties.

Desktop printers cannot heat up the entire chamber, they use a heated bed, generally with a maximum temperature of 100 °C, to improve part adhesion.

Quality and lifetime of an Industrial 3D printer

The components used to manufacture a desktop printer have a low quality because they are not designed to last long on the market.

Industrial 3D printers have been specifically designed to withstand high temperatures and long functioning hours. They are prepared to work continuously for many days, even weeks. The components mounted onboard ARGO systems are UL certified and have been tested to work for thousands of hours in critical conditions in terms of humidity, temperature, and vibrations. The overall costs of an industrial 3D printer might appear higher, but it has a longer usable lifetime.

Maximum print size with Industrial 3D printer

Common 3D printers generally print small to medium size parts, with build dimensions up to 200-300 mm per side.

If you need to print bigger parts, one should use a capable printer.

ARGO printers allow for printing parts with a maximum volume of 500x500x500 mm making the production of big parts possible, accurate and quick. Thanks to the two different configurations, Speed and Quality, the user can decide to print the parts with increased speed or enhanced details.

Industrial 3D printer and print success rate

You never know what can go wrong with a desktop 3D printer.

The extruder might clog, the process could suddenly stop for any reason. It is estimated that 40% of prints longer than 72 hours stop before completion. With the Roboze Automate technology, ARGO 500 printers always monitor every important parameter of the printer itself. In case of sudden issues, the printer will be able to simply pause. The pause will allow the user to do quick maintenance and to resume the printing job.

This feature, combined with the automation system that provides an advanced control of all the electronics in the printer, drastically increases the print success rate of the Roboze ARGO.

This parameter is important especially in large prints, where desktop 3D printers do not ensure the process to complete successfully.

Having a high print success rate allows you to rely on your production systems and to deliver your products on time.

Application sectors for industrial 3D printers

The use of Roboze solutions for additive manufacturing (AM) has spread across many industries. Here's the applications according to the main sectors of interest:

- Manufacturing

- Energy

- Mobility

- Aerospace

- Research

- Medical

The largest user of Roboze technology is the manufacturing sector. The energy and mobility sectors follow with about a fifth of applications each. In these industries the focus is largely the same: parts optimization and weight reduction as well as spare parts and tooling manufacturing.

Companies in general are still reluctant to produce parts and this is especially true for the heavily regulated industries which are Roboze's main customers. At first, companies prefer to use AM for production aid parts, such as tooling, jigs and fixtures, but the trend to use this technology for the production of end-use parts is growing. An example are seals, used in the energy sector, together with rotating elements. Molds are also applications required by manufacturing industries.

Finally, there are more specialized applications such as ducts, connectors and internals, which are more common in industries such as aerospace. In this context, the share of applications is lower because these high-tech sectors tend to produce smaller volumes of components than the manufacturing industry.

3D printing for the aerospace industry

The aerospace industry makes extensive use of 3D printing due to the ability to achieve significant mass reductions, also thanks to metal replacement, and design optimizations. Another determining factor is small production volumes resulting in high cost per part, while in 3D printing the cost per part remains the same regardless of quantity. As is the case in the energy and mobility sectors, tooling and spare parts are also driving factors.

3D printing for research

Research centers and educational institutes make extensive use of Roboze printing solutions both as a useful tool for research projects of centres, laboratories and universities, and for the production of experimental equipment quickly and at low cost.

3D printing for the biomedical sector

The adoption of 3D printing in the biomedical field is still growing, but more and more applications are being discovered that take advantage of this technology, such as surgical instruments, auxiliary devices and supports.

Roboze industrial 3D printers: case studies

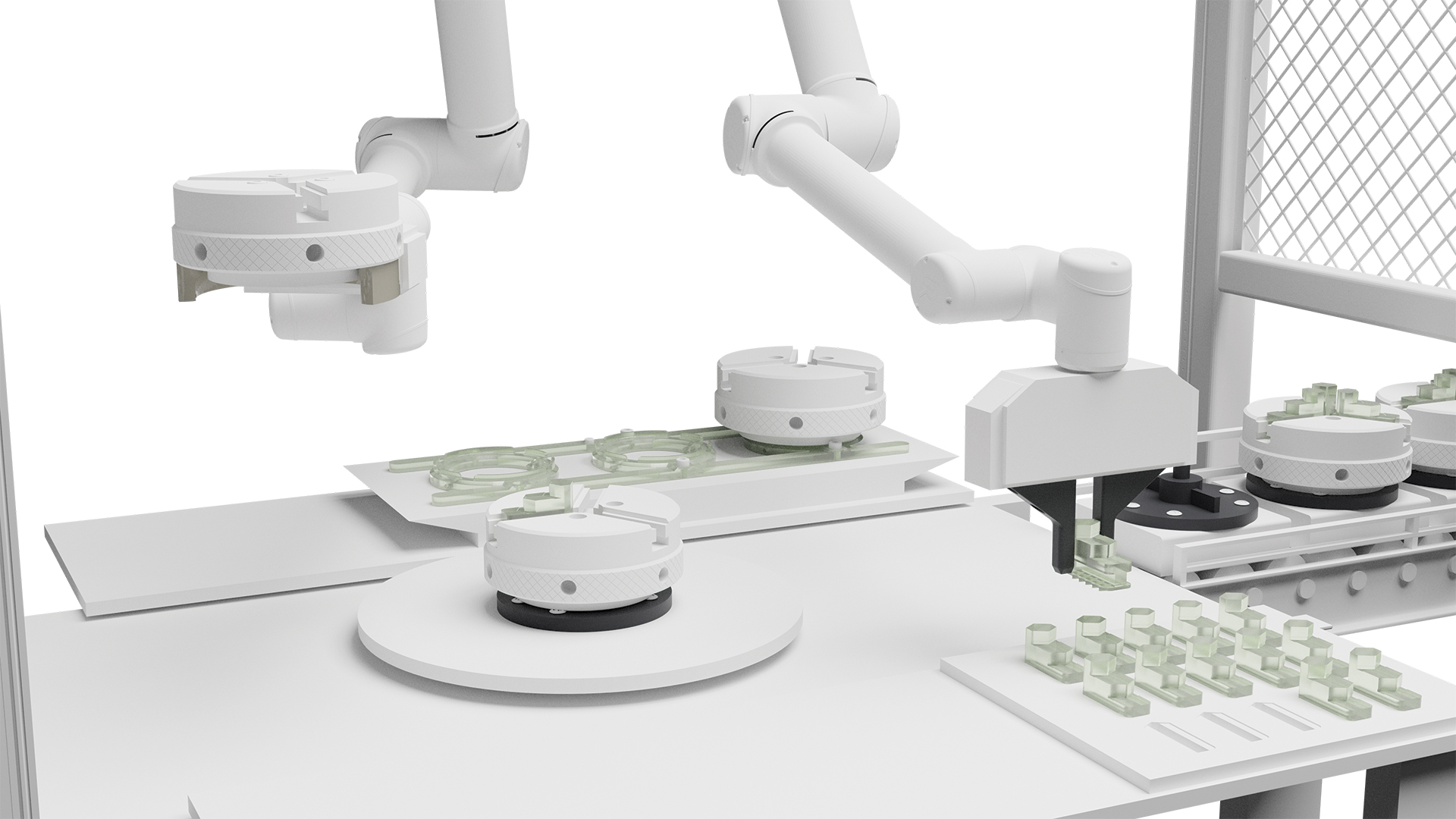

Grippers for automated production lines in the robotic industry

A company active in the manufacturing industry uses PEEK end effectors for pick and place operations in their automated production lines. Grippers have component-specific contours at their ends that enable them to pick up, grip, transport or guide components. Polymer grippers adapt to the objects they pick, without scratching them, whereas metal grippers tend to scratch the picked objects. PEEK grippers are common in regulated environments, where the speed of pick and place operations is high: due to the low wear rate of this material, his lifespan is higher than other plastics. PEEK grippers are also widely utilized in environments where cleanliness is fundamental: in fact, PEEK has a low water absorption and excellent temperature and chemical resistance.

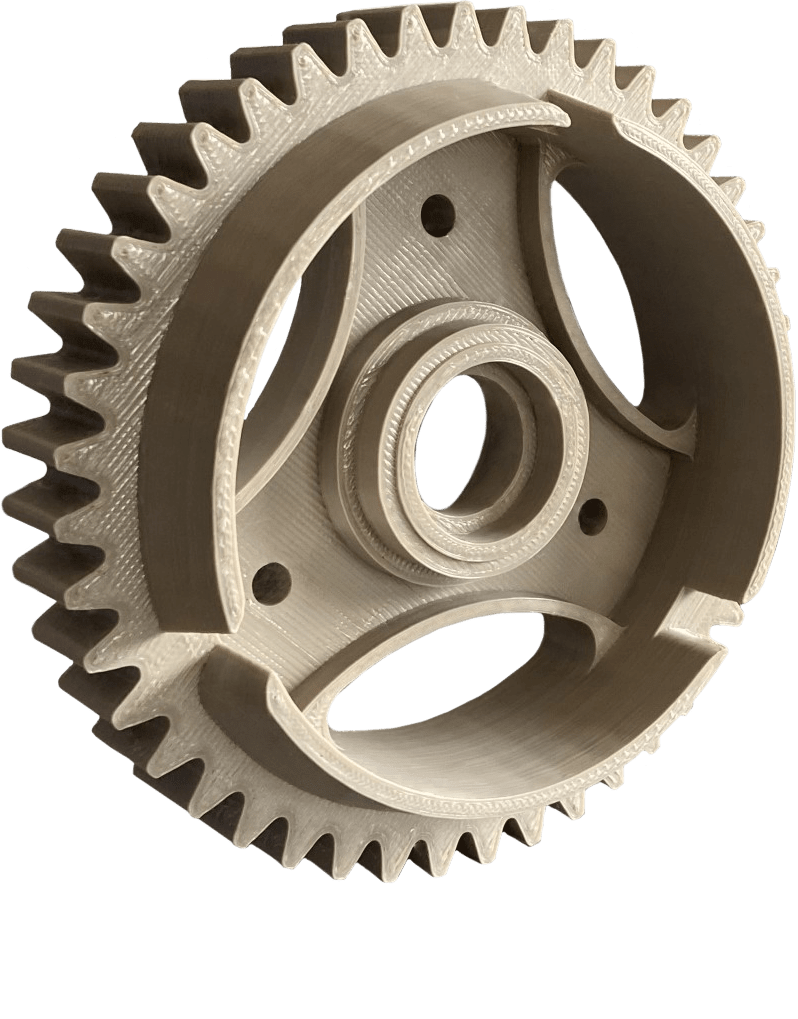

Closed impellers for the Energy sector

The use of Roboze 3D printed impellers has numerous advantages, both in terms of materials and production times. Thanks to the network of 3D Parts partners spread all over the world, companies always have a printer close to the final point of use, capable of producing closed impellers just-in-time and on-demand, significantly reducing lead times with minimal downtime. Proximity to the point of use of the impeller also shortens transportation times and reduces carbon emissions. By installing the closed impellers in Carbon PEEK 3D printed by Roboze ARGO 500 it is possible to obtain corrosion resistance and lighter parts of at least 50%, mechanical and hydraulic balance and optimization of the plant life cycle. The solution is ideal for applications in seawater, wastewater and corrosive environments.

- Tools for the lamination of carbon fiber hand lay-up in the aerospace sector

In the manufacturing process of carbon laminates, resin-impregnated carbon sheets (pre-preg) are cut in the desidered shape with the aid of one or more molds by an operator, then put into the autoclave to stimulate the polymerization of resins; the manual nature of the process requires low volumes and high production times and costs.

The customer, active in the aeronautical industry, 3D printed the molds, replacing the metal ones (steel and aluminum) obtained by removal with CNC machines. The mold, traditionally made of aluminum, was made with a carbon fibers reinforced polyamide (Roboze Carbon PA PRO). Roboze technology allowed to reduce costs and lead times, lighten tools and speed up the laminate modification and validation phases.

- Ducati case study

By 3D printing the tank heat shield in Carbon PEEK with Roboze ARGO 500, Ducati Corse, during the fantastic 2022 MotoGP season, reduced development times by about two weeks, saving 37% of the estimated costs for all iterations before realization of the final component. When passion, intuition and emotion come together, historic goals can be achieved! Check how you can improve your production processes with Roboze industrial 3D printing solutions. Roboze makes its know-how available to its customers in the design and production of industrial 3D printers and production of 3D On Demand parts with high-strength and high-temperature super polymers. Our consultants will listen to your requests and help you find the solution that's right for you. To ask us for personalized advice, write to info@roboze.com.